Z629 SATI EVO Self-loading Bale Wrapper

Compact and Lightweight Wrapper

Compact and Lightweight Wrapper

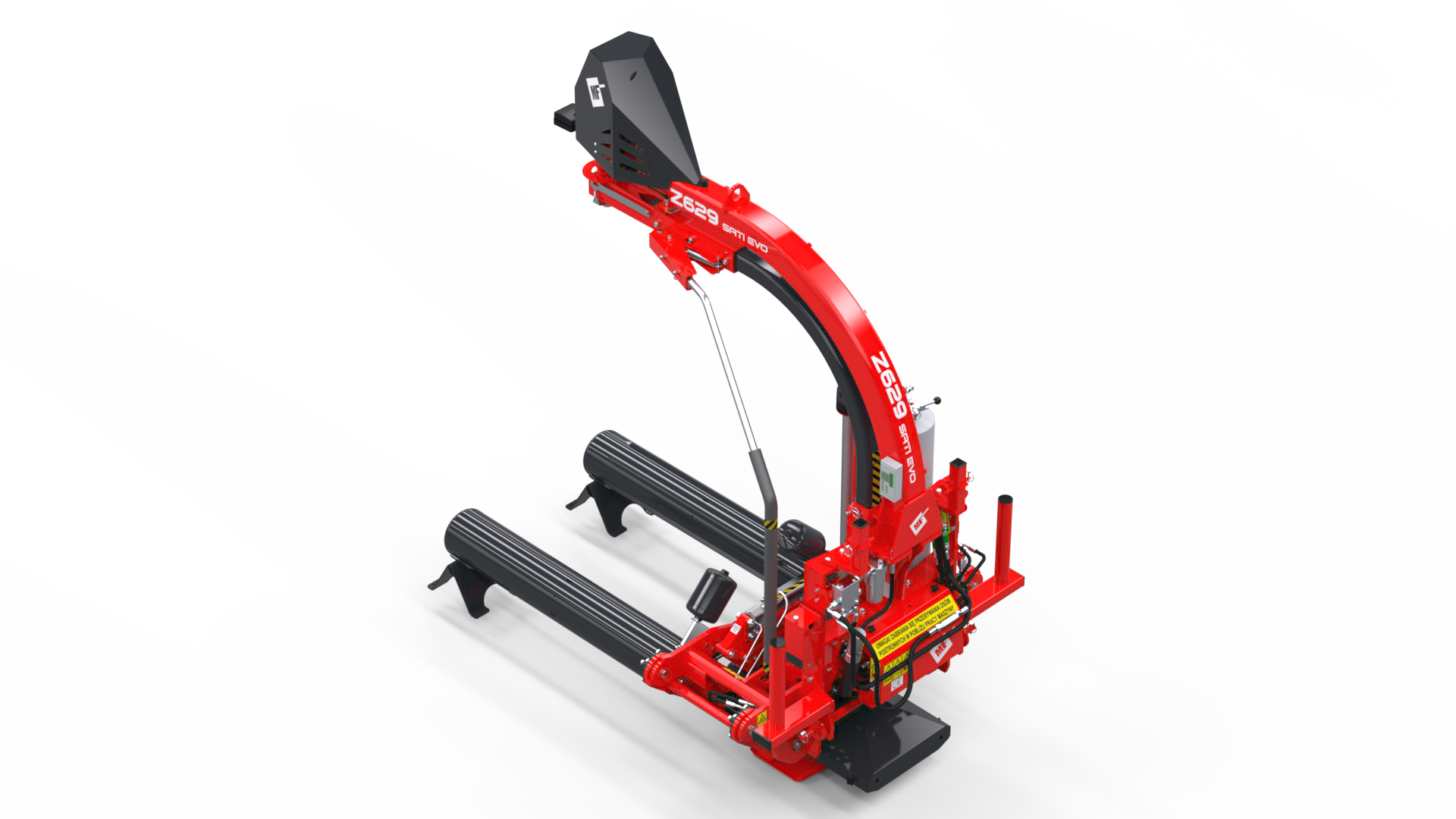

The Z629 SATI EVO self-loading bale wrapper is a technologically advanced solution engineered for efficiency and user convenience. With a compact design and a net weight of only 750 kg, it ranks among the lightest self-loading wrappers available, facilitating easy transport and handling. Suitable for mounting on either the rear or front three-point hitch (TPH) of a tractor, it offers full versatility in operation.

An automatic bottom-loading system, featuring specialized arms equipped with rollers, ensures seamless loading and unloading of bales with diameters ranging from 1200 mm to 1500 mm. The Z629 SATI EVO is a single-satellite machine that combines lightness with exceptional speed—a complete cycle (loading, wrapping, unloading) takes approximately one minute.

With a wrapping arm rotation speed of up to 30 revolutions per minute and automated control systems, the wrapper delivers maximum operational efficiency and full control over the process. Standard features include a 750 mm film feeder, an automatic film cutter, and an optional bale tipper that facilitates the stable placement of wrapped bales.

The Z629 SATI EVO is an excellent choice for farmers and enterprises seeking a reliable, compact, and efficient bale wrapper that ensures speed and precision at the highest level.

The Z629 SATI EVO bale wrapper is a fully automated single-satellite machine that eliminates the need for manual operation, enhancing user comfort and overall efficiency. Its versatile mounting system allows attachment to either the rear or front three-point hitch (TPH) of a tractor. Additional flexibility is provided by an optional transition frame – a Euro hitch adapter, enabling easy compatibility with various tractor models and implements.

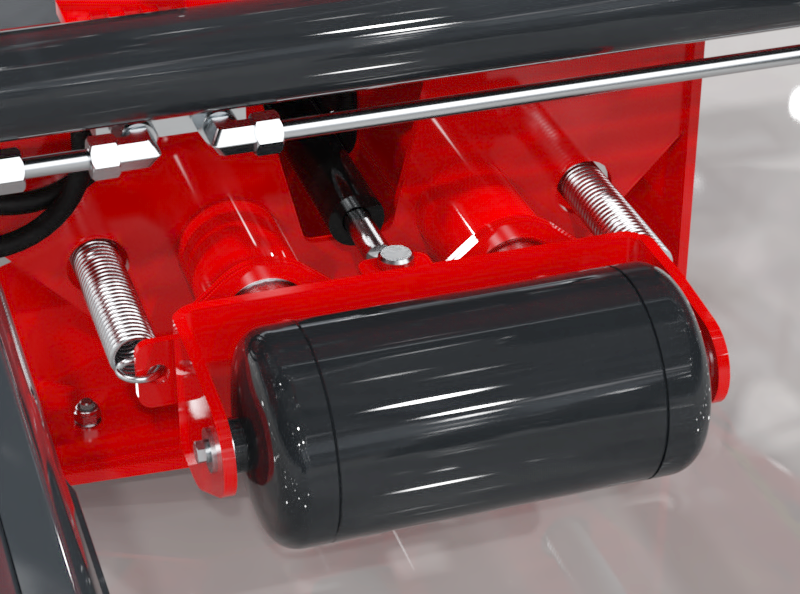

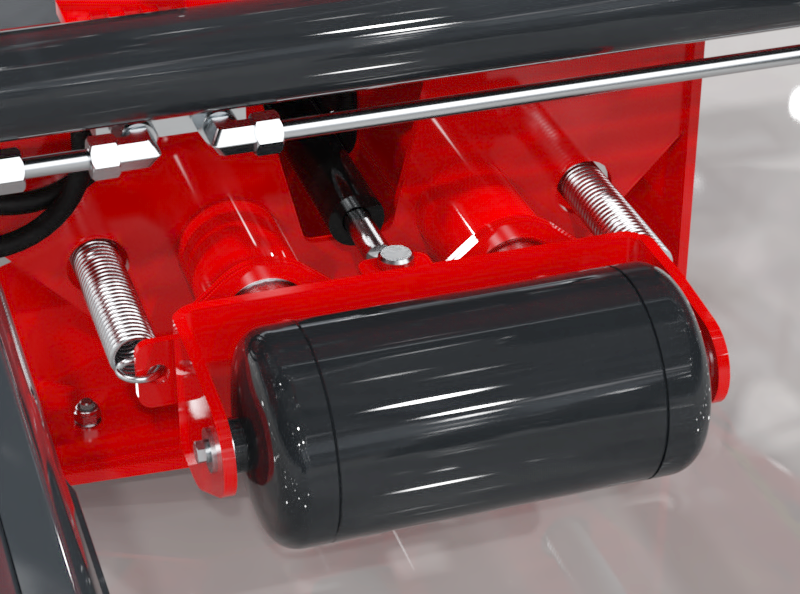

The bottom-loading system, equipped with specially designed arms and rotating rollers, guarantees safe and precise bale handling. The arms operate automatically, ensuring smooth folding and unfolding, which minimizes downtime during work. This design ensures that the loading process is fast and damage-free, allowing the operator to focus on maintaining high productivity levels.

Bale unloading is performed using the lower wrapping arms, providing a safe and efficient cycle completion without additional effort. The wrapper can be equipped with an optional hydraulic bale tipper, allowing bales to be positioned upright on their ends. This positioning prevents rolling, making transport and storage easier and faster. The integration of wrapping and bale positioning into a single process saves time, reduces the need for additional farm machinery, and directly contributes to lower logistical costs and increased efficiency.

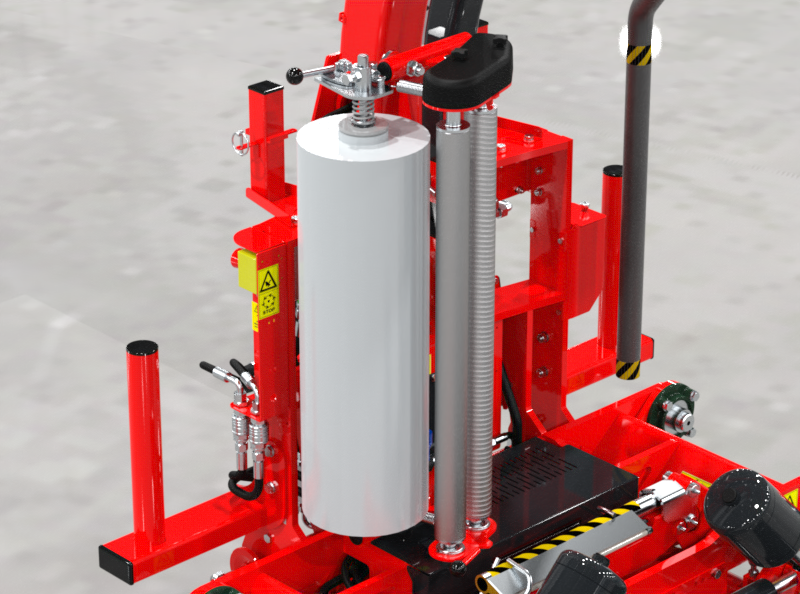

The Z629 SATI EVO bale wrapper efficiently wraps bales with diameters ranging from 1200 mm to 1500 mm and lengths of up to 1200 mm. The film is applied via an upper arm with a film dispenser, rotating around the bale at speeds of up to 30 rotations per minute. A built-in software-controlled speed limiter ensures maximum safety and machine stability. The automated speed monitoring system, complete with alerts for speed exceedance, helps prevent malfunctions and ensures smooth, reliable operation even under demanding field conditions.

Equipped with a 750 mm wide film dispenser, the wrapper delivers consistent and precise wrapping. Additionally, two spare film roll holders provide practical on-board storage, enabling longer operation without interruptions for film replacement – a key advantage for high-volume bale wrapping operations.

At the end of each wrapping cycle, the film is automatically cut by a modern hydraulic film cutter. Its robust design ensures secure film holding and clean, accurate cuts without the risk of tearing. Thanks to a throttle check valve, the closing speed of the cutter is adjustable, improving reliability and reducing film stress. This fully automatic system eliminates manual intervention and perfectly prepares the wrapper for the next cycle.

The entire cycle – loading, wrapping, and unloading – takes only about 1 minute, significantly boosting field productivity. This makes the Z629 SATI EVO an ideal choice for farms seeking high-speed bale wrapping with minimal downtime.

An advanced rotation counter sensor tracks the number of arm revolutions, ensuring the wrapper stops at the correct position every time. This prevents wrapping errors and guarantees even film distribution on the bale. The sensor’s adjustable position and resistance to interference contribute to the machine’s reliability even in harsh working conditions.

The rotational speed sensor maintains the optimal wrapping arm speed. If target speeds are not reached, the system alerts the operator with precise guidance for sensor adjustment, avoiding unplanned stops. This ensures that the wrapping process remains fully optimized and efficient, without straining the mechanical components.

To maintain the hydraulic system’s reliability, the Z629 SATI EVO is equipped with an active oil cooler with a thermostat. Keeping the oil at an optimal temperature not only enhances overall machine efficiency but also protects hydraulic components from overheating, extending their service life and reducing long-term operating costs.

The Z629 SATI EVO bale wrapper is operated via an intuitive control panel, giving the user full command over the entire bale wrapping process. The user interface is easy to navigate, allowing quick access to settings and functions. One of the key features is the ability to adjust the automatic loading time, with options ranging from 4 to 15 seconds, ensuring the machine adapts to your workflow preferences and field conditions.

*The machine's net weight and dimensions given for the standard version do not include optional equipment.

We deliver valuable and functional solutions that meet your specific needs and help you achieve better results in the field.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.

Home / Products / Bale wrappers / Z629 SATI EVO Self-loading Bale Wrapper