The T659 BEL-MIX is a mixer feeder with one vertical mixing auger and two discharge chutes.

It is available in capacities from 5 to 10 m3.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.

Home / Products / Feeder wagons / T659 BEL-MIX Lowered Single-auger Feeder Wagon

Technical GVW

5490-7490 kg

Technical load capacity

1900-2300 kg

Container capacity

6-10 m3

Take a closer look

Explore the BEL-MIX lowered from all sides with a 360o animation.

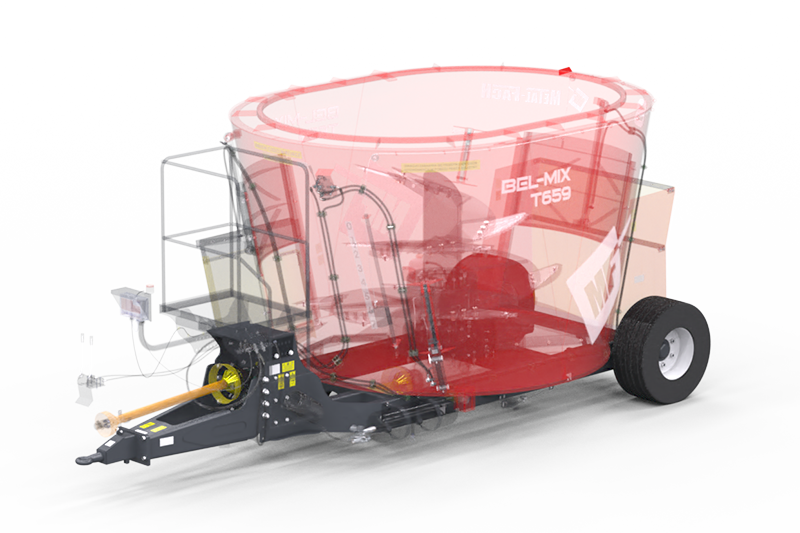

The T659 BEL-MIX Lowered Feeder Wagon is designed for narrow and low feed aisles. Its compact size and low power requirement make the machine ideal for most farms. In this model, the axle has been moved backwards while retaining the basket and floor construction of the standard model. An additional advantage of such axle arrangement is the increased pressure on the tractor hitch and thus increased pulling power. Despite a ground clearance that is lower than in standard models, this design allows for a variety of unloading solutions.

It allows you to control the mixing of feed in a simple, easy and safe way.

The robust walls of the container are made of S355 grade steel with increased abrasion resistance. This guarantees the highest quality and many years of machine operation.

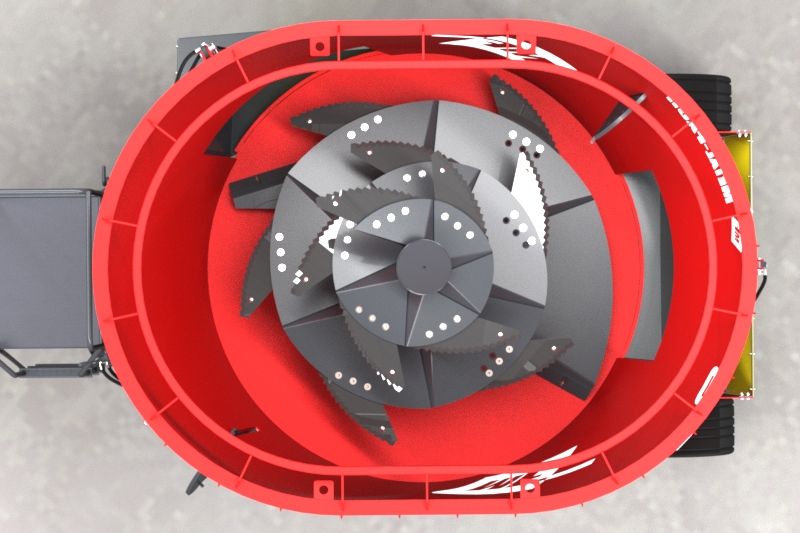

The container floor is made of 20 mm thick S355 grade steel. The shape of the container and the matching mixing auger ensure that the ideal TMR is prepared with minimum power requirements.

The mixing and cutting auger made of S355 steel is mounted to the container floor. It is equipped with 10 PREMIUM carbide-faced blades as standard. It is possible to retrofit the auger with an additional 2 or 3 blades.

The auger is finished with a 10 mm thick scraper. A magnet is fitted as an option to the scraper to catch metal impurities in the TMR portion being mixed. This system significantly reduces pre-stomach injuries and disorders.

Two mechanical counterblades are fitted in the standard version. As an option, the machine can be retrofitted with a hydraulically controlled counterblade. The ideal arrangement of the adjustable counterblades supports the cutting and mixing process. The counterblades can be slid in or out as required.

The Mixer Feeder is fitted with a welded anti-overflow ring as standard. You can replace it with a screw-on ring.

It is an element of the container that prevents feed from escaping during mixing and reinforces the container structure.

A versatile, programmable weighing system allows you to create feeding strategies, distribute feed according to a specific strategy and collect feeding data necessary to weigh separate feed components correctly.

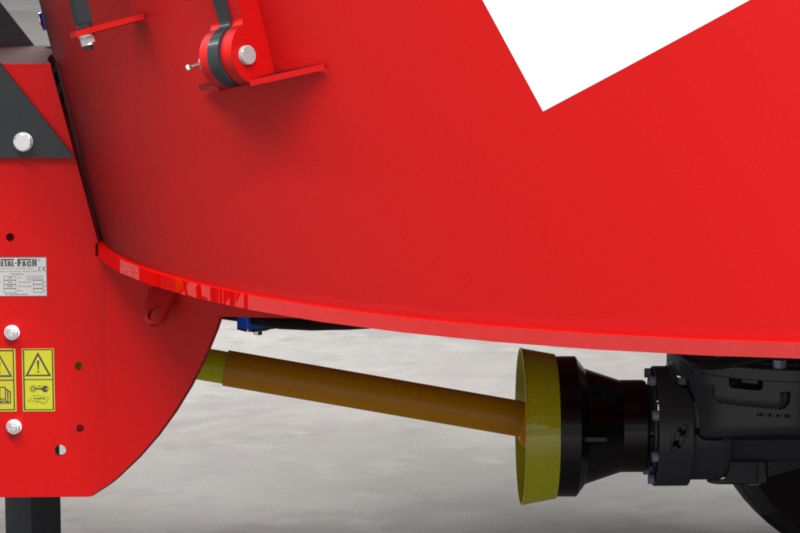

Every T659 BEL-MIX Lowered Feeder Wagon in the standard version is fitted with a discharge window with discharge chutes on both sides.

Discharge windows ensure that feed is distributed with ease directly to the feeding trough. A protective apron prevents feed from being thrown outside the trough.

Depending on the user’s preference, the chutes can be placed on either side of the tank: front, rear, left or right.

This makes it possible to distribute the feed in every barn, even in buildings without a separate entrance.

The equipment shown in the photos may vary depending on the version chosen.

| Model of machine | T659/3 | T659/3 | T659/3 | T659/3 | T659/3 |

|---|---|---|---|---|---|

| Type of homologation | - | - | - | - | - |

| Transport speed (max.) [km/h] | 30 | 30 | 30 | 30 | 30 |

| Technical GVW [kg]* | 5490-7490 | 5490-7490 | 5490-7490 | 7090-7490 | 7090-7490 |

| GVW [kg]* | 3860-5190 | 3860-5190 | 3860-5190 | 4790-5190 | 4790-5190 |

| Technical load capacity [kg]* | 1900 | 2000 | 2100 | 2200 | 2300 |

| Homologated load capacity [kg] | - | - | - | - | - |

| Weight [kg]* | 3800-4000 | 3900-4100 | 4000-4200 | 4100-4300 | 4200-4400 |

| Vertical hitch eye load (max) [kg] | 2500 | 2500 | 2500 | 2500 | 2500 |

| Cargo box capacity [m3] | 6 | 7 | 8 | 9 | 10 |

| Length / Width / Height of the cargo space [mm]* | -/2200/1480 | -/2200/1500-1560 | -/2200/1660-1740 -/2300/1560-1620 | -/2300/1710-1800 -/2400/1610-1670 | -/2300/1870-1960 -/2400/1750-1840 |

| Overall dimensions without extensions Length / Width / Height [mm]* | 5250-6250/ 2200-3000/ 1970 | 5250-6250/ 2200-3000/ 1990-2050 | 5250-6250/ 2200-3000/ 2050-2230 | 5250-6250/ 2200-3000/ 2100-2290 | 5250-6250/ 2200-3000/ 2240-2450 |

| Height of the cargo floor from the ground [mm]** | 445 | 445 | 445 | 445 | 445 |

| Loading height | 1970 | 1990-2050 | 2050-2230 | 2100-2290 | 2240-2450 |

| Tires** | Delcora 30x11.5-14.5 | Delcora 30x11.5-14.5 | Delcora 30x11.5-14.5 | Delcora 30x11.5-14.5 | Delcora 30x11.5-14.5 |

| Power requirements (min.) [KM] | 50-70 | 50-70 | 50-70 | 70-90 | 70-90 |

* Depending on the equipment

** Standard equipment

The dimensions of the width and thus the floor of the Mixer Feeder as well as the inclination of the container walls can be changed by the customer. Changes to the above-mentioned dimensions affect the main dimensions of the Mixer Feeder (length, width, height). Such modifications must be agreed with the seller.

We deliver valuable and functional solutions that meet your specific needs and help you achieve better results in the field.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.