Extra offer especially for You! Buy a T711 series trailer or T739A trailer and receive a tarpaulin with frame for free!

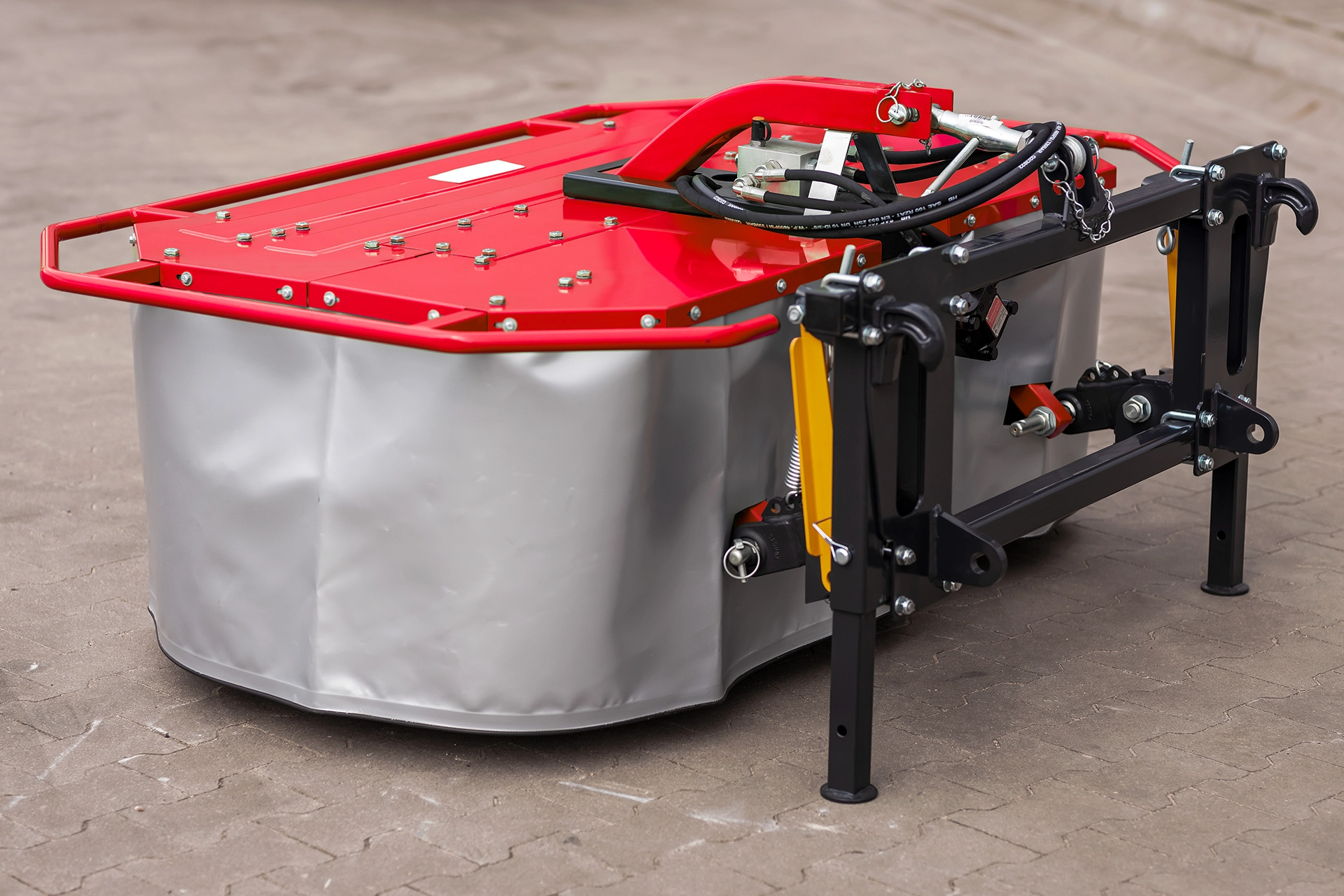

Metal-Fach provides a wide range of agricultural trailers: dump trailers, sidewall trailers, monocoque trailers, volume trailers, and bale platforms. Discover our solutions to boost your farm’s efficiency.

Metal-Fach is synonymous with durability and reliability in agriculture. As an experienced manufacturer of agricultural machinery, we provide solutions that simplify the daily work of farmers worldwide.

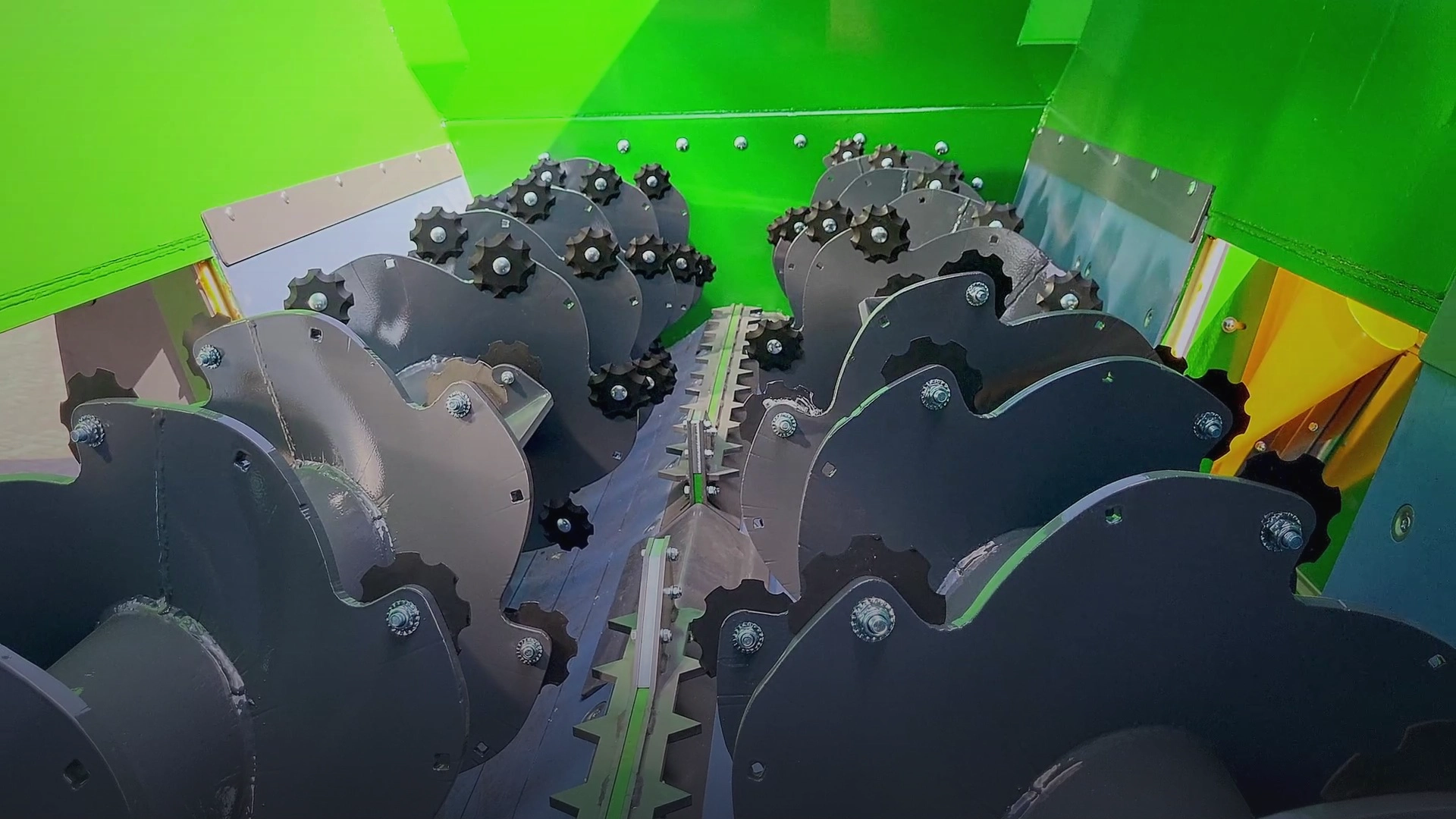

We continuously expand our product range, introducing modern agricultural machinery that enhances productivity and work comfort. Explore our newest solutions designed for farmers who value durability, precision, and advanced technology.

We are a dynamic company specializing in the production of advanced agricultural machinery—modern tools that support innovative farming. Our passion for excellence drives us to continuously improve and deliver top-quality solutions.

Our portfolio includes not only technologically advanced machines but also a commitment to the future of agriculture. We strive to increase efficiency and sustainability, enabling farmers to achieve the best results with minimal environmental impact.

Our company is built on values such as innovation, quality, partnership, and responsibility. We believe in creating relationships based on trust and cooperation. Our machines are not just tools but a pathway to achieving shared goals. We aim to transform agriculture by providing modern, efficient, and eco-friendly solutions that lead to abundant harvests.

Join us as we step into the future of farming—building a sustainable and productive environment for new successes.

We invest in innovation and precision agriculture. Our machines are compatible with modern farm management systems, allowing for greater efficiency and resource savings.

Our agricultural machines are working in over 40 countries! Check where the nearest Metal-Fach dealer is and join the community of satisfied customers.

Szukasz atrakcyjnego finansowania dla swojego biznesu? Chcesz zainwestować w nowoczesne maszyny i sprzęt? Mamy dla Ciebie idealne rozwiązanie. Oferujemy finansowanie fabryczne, które daje Ci wszystko, czego potrzebujesz do rozwoju Twojej firmy.

Nova to linia solidnych naczep do transportu ciężkiego. Innowacyjne technologie, wytrzymałe konstrukcje i bezpieczeństwo użytkowania.

Nasze kontenery modułowe to nowoczesne, wytrzymałe i elastyczne konstrukcje, które można dostosować do różnych potrzeb.

We deliver valuable and functional solutions that meet your specific needs and help you achieve better results in the field.

Fill out the form and our consultant will contact you as soon as possible.

Please fill out all fields marked *.

Completing the form means that the personal data provided therein will be processed for the purpose of establishing contact. Find out who processes your data and how.